www.randysworkshop.net

www.randysworkshop.net|

I' ve been very happy with my Lenz2 wings that I bought from WindGenKits.com. They have held up thru several severe storms which bent the attachment arms and center support tube. That has been repaired and they are currently still spinning away making power for me. Since they are a drag style blade they don't spin very fast. I have found that the F&P motor as a generator puts out about 0.9 watts per RPM. For me to get more power, I need the motor to spin faster. Ah, but I am getting ahead of my self. |

|

|

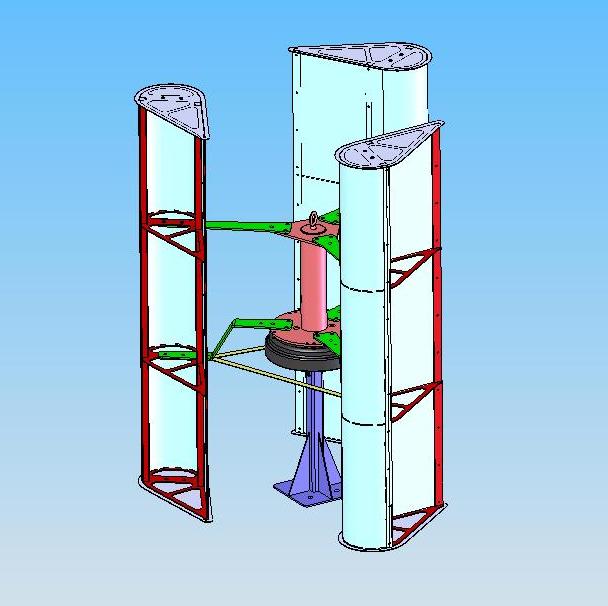

One of the main problems with this wonderful motor has been how to mount it. If you have looked at my mounting page you will see that my latest idea is to use a trailer hub and spindle. This looks very promising! I went ahead and modeled up a new mount utilizing the Lenz2 wings available from WindGenKits.com. When I went to their website to order another set of blades, I came across their new R2-40 assembly utilizing their new "Razor" blades. Boy did I get excited! I just knew this was the route to take. Unfortunately their website is down. I don't know the status of their business.

|

|

|

I was not happy with having to put a spacer between trailer hub and my adaptor plate to get the correct magnet spacing, so I slept on it and came up with the idea of putting the adaptor plate on the other side of the hub flange. I could then use the wheel studs not only to locate the plate but also to hold it in place. I had to knock out the studs and press them back in, but that was not too difficult. A hammer to knock them out and a stack of washers, a nut and a socket wrench to pull them back in place. The flange is about 5/8" thick so that ment repositioning the stator mounting flange on the spindle.

The distance from the bottom of the bearing to the flange face is now 1.500" |

|

The stator mounting flange on the spindle will need to be "trued" up in a lathe after welding. Welding heat can easily distort metal assemblies, that is why you usually machine parts after welding. Boy does it spin easy on these new tapered wheel bearings. It was very difficult for me to feel any cogg. |

|

As you can see I am getting close to finishing this project. I need to work on the wings next. The finished unit should look similar to the picture at the top of the page. Simple, and very functional. Let me know if you are interested in duplicating this unit. I'll try to post more as I progress. P.S. I have plenty of F&P motors available. |